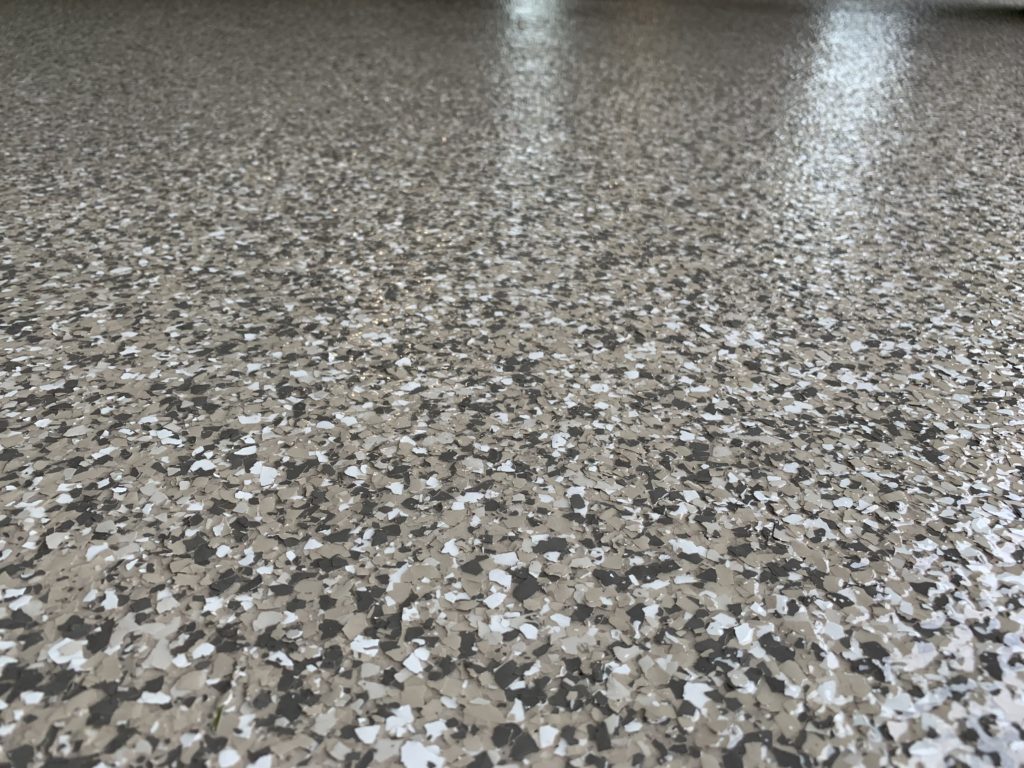

Exotic Auto Floors for Showrooms

The benefits of our Epoxy / Polyaspartic coatings on an auto or motorcycle showroom floor include natural clarity, non-yellowing, scratch resistant and easy, labor saving maintenance. Color and design options are unlimited. We are based in Kenmore, Washington but service the entire north west.

Decorative Options

- Base Colors – There are 12 base colors which can be combined to create an optimal shade with limitless results.

- Color Chips – Decorative chips come in numerous sizes and color combinations. Chips colors can be mixed to match your interior décor.

- Clear Coats – Your concrete can be dyed or stained then sealed with a polyaspartic clear coats

Non Slip Features

Very fine glass aggregate can be built into each coat rather than broadcasting over the surface. When non slip aggregate is broadcast over the top coat, it has the tendency to become dislodged from wear and tear. We mix aggregate into the coatings for long term performance.

This method provides a non slip surface that lasts for years, exceeding OSHA and ADA Coefficient of Friction guidelines.

Clarity and Labor Saving Maintenance

One of the unique benefits of high quality polyaspartics is that they are non yellowing, scratch resistant and exhibit tremendous clarity. This makes for a true, vibrant reflection which will enhance your product display whether an automobile, motorcycle or any other product.

The scratch resistant feature prevents dirt buildup which dulls the finish. Simply clean the surface with water and small amount of detergent and whisk away with a neoprene squeegee. This cleaning process is fast, effective while avoiding the need for a mop which does nothing more than moving dirt around.

Durability, Adhesion and Rapid Cure

Our surface preparation is the most critical part of application. We grind the surface to remove the high spots in the concrete. This helps us achieve a blemish free showroom quality finish.

The floor grinding process also serves to open the pores of the concrete so that our polyurea can absorb into the surface becoming part of the floor. The first coat is typically 5-6 mills thick followed by an 11-12 mil finish coat.

Polyaspartics cure quickly allowing us to apply two coats in a single day with a return to service the next day.